Case story

Drainage and Filtration, Thermal, CA

United States, California, Thermal

Case Study Form

|

Application |

Drainage and Filtration |

Job owner |

Coachella Valley Water District |

|

Location |

Thermal, CA |

Engineer |

Coachella Valley Engineering Department |

|

Product |

Mirafi® FW700 |

Contractor |

Jones Brothers Construction Company |

|

|

|

Date of Installation (m/y) |

March 2011 |

THE CHALLENGE

The City of Thermal, (Coachella Valley) California was in desperate need of water and sewer improvements and investigated solutions provided by geosynthetics. Coachella Valley wanted a geotextile that was durable and would also provide a controlled flow rate. The new sewer systems needed to be long lasting and thus using the proper materials was a very important initiative.

THE DESIGN

TenCate Mirafi® FW700 woven geotextile was chosen by the Coachella Valley Engineering Department as a suitable geotextile for this project. Mirafi® FW700 was chosen because of its durability and its flow rate of 18 gal/min/ft2. The strength and flow provided by Mirafi® FW700 was perfect for the application. By using this woven geotextile, the engineer was confident that it would provide the necessary amount of flow that was needed. In addition, it would provide durability and performance that would last throughout the years. These components were very important for providing a proper drainage platform for this application.

THE CONSTRUCTION

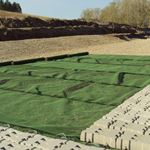

First, the contractor dug out the old sewer pipes and set up sheer walls so they had a safe working area. They used a “pipe rail device” over which they slid the roll cores. They pulled the product down and placed a layer of Mirafi® FW700 at the bottom of the trench on the subgrade. The contractor then filled 8” of ¾” crushed aggregate on top of the geotextile. The new sewer pipe was then lowered into the trench on top of the Mirafi® FW700 and the ¾” crushed rock. After the pipes were secured, ¾” crush aggregate was placed over the pipe 8” and filled the trench. Mirafi® FW700 was then cut and wrapped around the remaining aggregate, creating a continuous layer between the native soils above and below and the ¾” aggregate. This provided the necessary platform for drainage and filtration requirements for the project.

THE PERFORMANCE

The use of TenCate Mirafi® FW700 provided strength, drainage and filtration for the city of Thermal’s water and sewer improvements.

- The strength of Mirafi® FW700 insured that the 3/4” aggregate would stay in place.

- The flow of 18 gal/min/ft² allowed for sufficient filtration & drainage.

- Mirafi® FW700 also provided separation of the native soil & the 3/4” aggregate.

The result was a completed water and sewer improvement project that will last for years, providing improved proper water and sewer services for the city of Thermal.

,.jpg?w=150&h=150&action=crop)

,.jpg?w=320&h=180&action=crop)

.jpg?w=40&h=40&action=crop)